Micromechanical actuators have enormous applicative potential in numerous technologies such as microfluidics, drug delivery, artificial muscles, opto/micromechanical switches, micromirrors, microrobots.

Actuation at microscopic scale is mainly performed:

| Electrostatic actuation | Piezo actuation | Electromagnetic actuation | Thermal actuation |

|

|

|

|

|

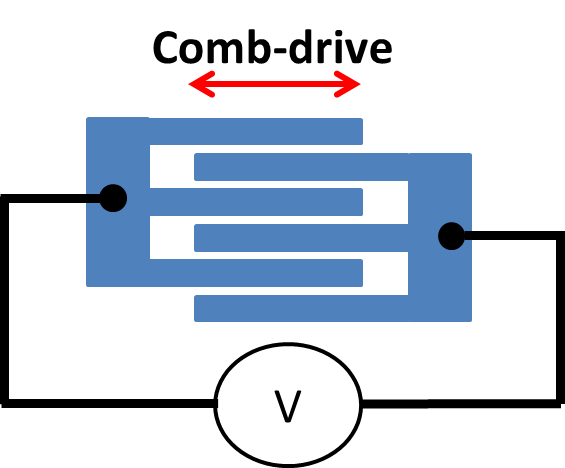

Electrically through capacitive couplings, for example in comb-drive systems |

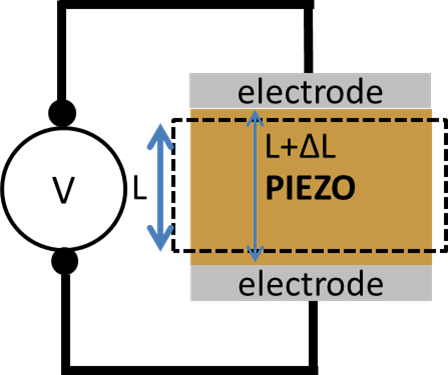

Using piezoelectrics/electrostrictive materials that act as active elements in deformable structures |

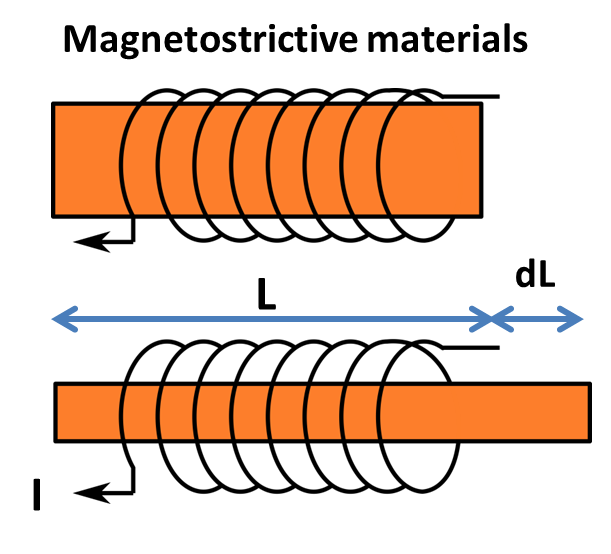

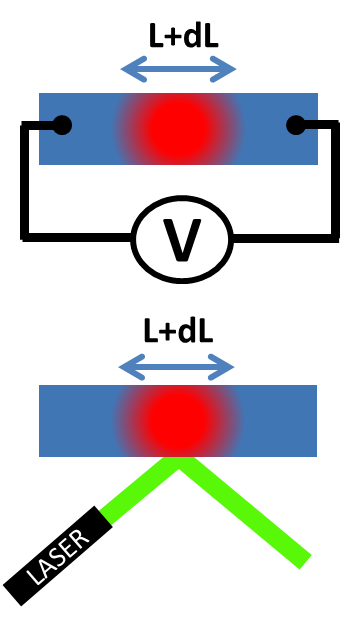

Electromagnetically using integrated coils coupled with micromachined magnets or magnetostrictive elements | Electrothermally (i.e. Joule heating) or through light irradiation, exploiting the phase changes of specific materials with temperature or thermal expansion |

|

Each approach has his own Pros and Cons, but best performances are generally characterized by high relative elongation, large force output and high actuation speed. Power consumption is also an important issue for most targeted applications. Organic materials usually have high displacement, but low force and speed and are difficult to integrate with current solid-state devices. Shape Memory Alloys have a large elongation times force product and are employed in thermal-based actuation schemes. However, they suffer nanoscaling and need quite large temperature variation to perform their goal. |

|

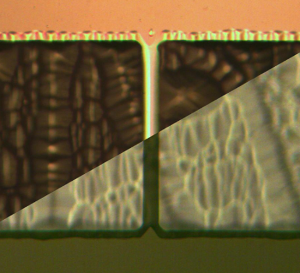

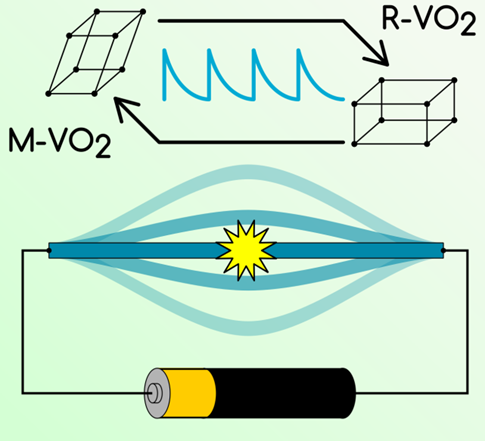

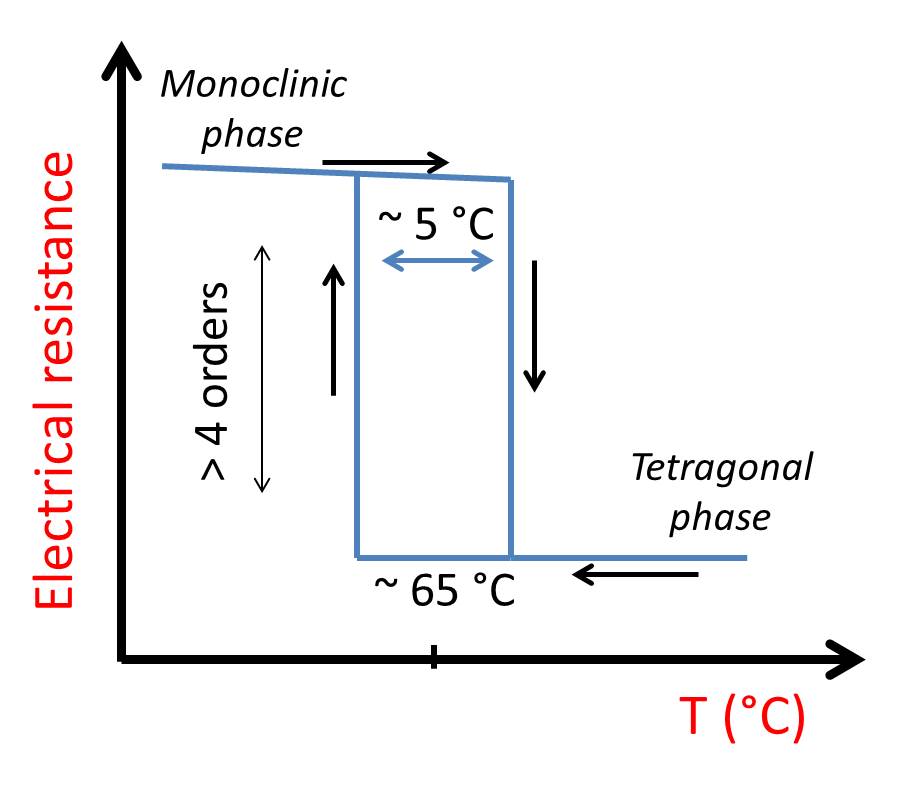

| Vanadium dioxide (VO2) has been recently considered as an optimum active material in micro/nanoactuators, due to its sharp solid state phase transition (SSPT) at 68°C from monoclinic (M1-M2) phases to the rutile type tetragonal (R) phase that in single crystal can produce strain up to 1% and large applied forces [1]. This solid state phase transition is accompanied by a Metal Insulator Transition with a change of electrical resistivity of more than 4 orders of magnitude. Remarkably, its phase transition is intrinsically fast (ps). This SSPT presents also hysteretic behavior. Regarding the employment of this SSPT to drive micromechanical devices, efficient actuation in VO2 microbeams or prototypical thin film structures has been demonstrated [2, 3]. However the full potentialities of developing active nanodevices with VO2 are still unexplored. This especially considering the role of nanodomains formation and manipulation in VO2-based structures and the contribution of strain to the shape and mechanical resonances of the final device. | The VO2 Solid State Phase Transition |

|

We aim at realizing micro and nanomechanical devices exploiting the change of lattice parameters of VO2 thin film nanostructures upon heating. Although energy efficiency of thermal-based actuation schemes is generally low, thermal actuation at nanoscale can be particularly interesting due to the easiness of fabrication associated with large applied forces. We are working on all-oxide Micro-Electromechanical Systems, using fabrication protocols specially developed for oxide materials. Films are grown by Pulsed Laser Deposition on single crystal substrates and buffer layers in order to control VO2 film orientation and drive the directions of lattice expansion of our microdevices. Growing VO2 films on oxide substrates allows to achieve performances near to those observed in single crystals [4]. |

|

For further readings >

[1] Powerful, multifunctional torsional micromuscles activated by phase transition Liu K, Cheng C, Suh J, Tang-Kong R, Fu D, Lee S, Zhou J, Chua L O and Wu J Adv. Mater. 26 1746–50 (2014)

[2] Giant-amplitude, high-work density microactuators with phase transition activated nanolayer bimorphs Liu K, Cheng C, Cheng Z, Wang K, Ramesh R and Wu J 2012 . Nano Lett. 12 6302–8 (2012)

[3] Nanomechanical actuation from phase transitions in individual VO2 micro-beams Guo H, Wang K, Deng Y, Oh Y, Syed Asif S A, Warren O L, Shan Z W, Wu J and Minor A M Appl. Phys. Lett. 102 231909 (2013)

[4] Nonpercolative metal-insulator transition in VO2 single crystals Mun B S, Chen K, Yoon J, Dejoie C, Tamura N, Kunz M, Liu Z, Grass M E, Mo S K, Park C, Lee Y Y and Ju H Phys. Rev. B - Condens. Matter Mater. Phys. 84 113109 (2011)