|

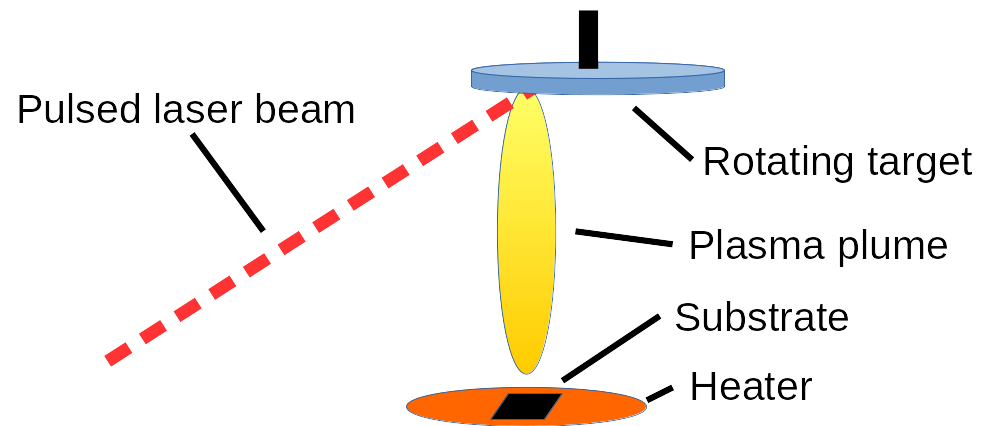

Pulsed Laser Deposition (PLD) is a versatile physical vapor deposition technique to fabricate complex thin films. The general principle of PLD is quite simple: a high-power pulsed laser beam (usually an excimer laser) is focused to a pellet (target) of the desired material located in a vacuum chamber. The laser beam evaporates ions, neutral atoms and species from the target in what is said “the ablation-plume”. In front of the target, at about 50 mm, is located a substrate where a film made of the elements and stoichiometry contained the target itself starts to grow. Composition of the target material is usually that of the wanted phase, but off-stoichiometric targets are sometimes prepared to compensate for evaporation of high volatility elements or resputtering from the film surface. The typical film grow rates are in the 0.01 nm/laser pulse range, about 100 nm/hour for a 3Hz pulse repetition rate. Good film crystal quality is achieved by tuning the different growth parameters. For example the substrate temperature, which is typically of few hundreds of degrees Celsius, the oxygen pressure in the chamber (for oxides growth), usually between 1 mbar and 10-6 mbar, the intensity of the laser, that can reach several hundreds of milliJoules per pulse, equivalent to few MW of power (the laser pulse duration is about 20 ns). Target-to-substrate temperature is also an important parameter to consider when depositing films by PLD. A schematic sketch of the PLD process is illustrated in the figure. The ablation-plume impinges onto a crystalline substrate maintained at high temperature. The atoms diffuse onto the surface and create a new crystal structure mimicking the existing one. |

|||

|

|

||

|

This process is called epitaxial grows and refers to the deposition of a crystalline layer that is in registry to an underlying crystalline substrate [1]. Epitaxial growth requires the crystal symmetry and lattice parameters of the substrate to be compatible with the growing film, otherwise polycrystalline, amorphous or even wrong chemical phases will result. If a well-matching substrate is used, a single-crystalline thin film can still be obtained, where the growing lattice adapts with continuity with the one of the substrate. Mismatch of the lattice parameters between the film “bulk” parameters and the substrate results in a built-in strain that can modify the physical properties of the deposited film. Built-in strain can be tuned by properly choosing the substrate and film thickness as well as by slight variations of films stoichiometry. Built-in strain is an important and somehow critical parameter for the fabrication of freestanding oxide microstructures, as it is a primary parameter in determining the shape of the suspended microstructure.

Fabrication of freestanding oxide structures > |

|||

|

For further readings > [1] Growth and Novel Applications of Epitaxial Oxide Thin Films by Agham-Bayan Posadas, Mikk Lippmaa, Fred J. Walker, Matthew Dawber, Charles H. Ahn, Jean-Marc Triscone in K. Rabe, C. H. Ahn, J—M. Triscone (Eds.) Physics of Ferroelectrics Topics Appl. Physics 105, 219-304 (2007). |

|||