|

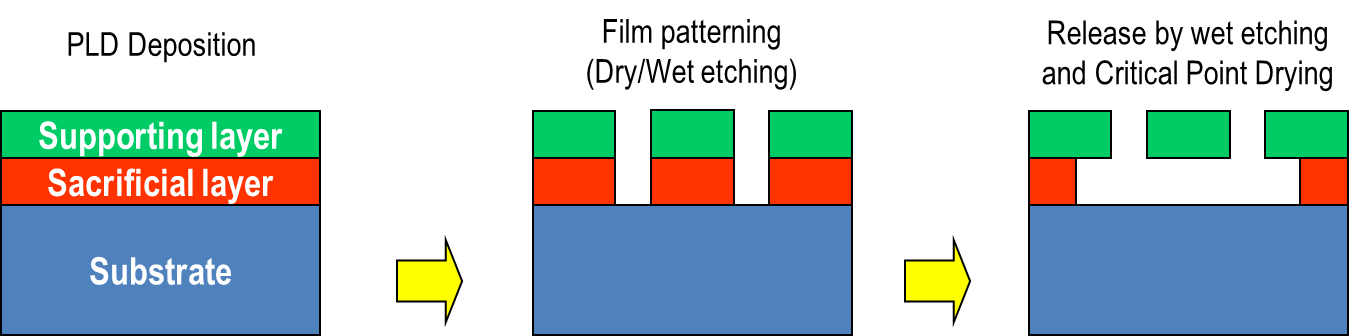

Realization of Micro-Electro-Mechanical-Systems typically requires the fabrication of freestanding regions. The fabrication protocols for Silicon-based devices are well developed and ordinarily used in industries (i.e. surface or bulk micromachining). In the case of oxide materials, these protocols are less developed and standardized. We developed through the years different etching and fabrication protocols that allowed us to realize freestanding microstructures with oxide thin films and heterostructures [1-3]. These protocols require the use of a sacrificial layer and acid baths of different compositions. As we like to work with high-quality crystalline materials, the sacrificial layers must be epitaxial to allow for epitaxial growth of the envisaged supporting layer. |

|

|

|

|

|

Our processes can be summarized as displayed above. The thin film heterostructure comprising the sacrificial layer is deposited by PLD and a resist mask is patterned by optical or electron beam lithography. The sacrificial layer can also be the substrate itself, as in the case of VO2-based devices. The film/heterostructure is then etched by Argon milling or wet etching and, after that, the resist is removed in acetone. At this stage the microstructure is still clamped and its release is achieved by using selective etchants. As an example, we realized freestanding SrTiO3 microstructures by fabricating a SrTiO3/(La,Sr)MnO3/SrTiO3 heterostructure where the (La,Sr)MnO3 works as sacrificial layer [1,2] or, similarly, we can fabricate (La,Sr)MnO3 freestanding microstructures by depositing a (La,Sr)MnO3 thin film and etching the SrTiO3 substrate [3]. This is possible thanks to the high etching selectivity provided by HF and HCl on these two materials, where HF etches SrTiO3 but not (La,Sr)MnO3 and HCl etches (La,Sr)MnO3 but not SrTiO3. |

|

|

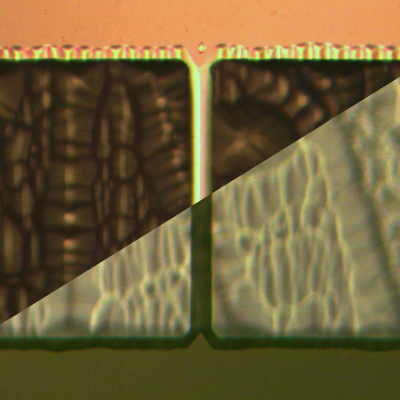

The fabrication of VO2 freestanding structures starts from the deposition of a VO2/TiO2 bilayer that is physically etched by Argon milling into the desired geometry. Once the MgO substrate is exposed, the patterns are made freestanding using 8.5 % H3PO4 water solution, which selectively etches the MgO substrate only. Drying is performed by a Critical Point Dryer to avoid stiction and rupture of the structures. The picture on the right shows an optical image of a freestanding VO2/TiO2 microbridge made with our process. The picture is a combined image made in reflection (upper diagonal) and transmitted (lower diagonal) light mode; freestanding and clamped regions shows a different coloration. The etched MgO substrate is also visible as a wavy surface in the background. |

|

|

Oxide materials are resilient to harsh conditions, in particular high temperatures. This allows to develop more complicated fabrication processes where, as an example, a free-standing device can be placed back into the PLD chamber and employed as a pre-patterned growing substrate for a new thin film. We observed that the grown films retain good electrical properties typical of the searched stoichiometry. Further depositions onto these MEMS structures of chemically-sensitive compounds that would be impossible to pattern by conventional methods can be thus envisaged. One of the key points for the realization of freestanding structures is the control of the final shape of the suspended region. Mechanical stresses originating in the deposited films result in unwanted deformation of the freestanding regions and consequent change of their mechanical response with respect to that expected from the designed geometry. One of the goals of this project is to address this important issue. Resonant Mechanical Actuation of Microbridges using a DC Voltage Bias > For further readings > [1] All-oxide crystalline microelectromechanical systems: Bending the functionalities of transition-metal oxide thin films Pellegrino L, Biasotti M, Bellingeri E, Bernini C, Siri A S and Marré D Adv. Mater. 21 2377–81 (2009) [2] Fabrication and electromechanical actuation of epitaxial SrTiO3(001) microcantilevers Michele Biasotti, Luca Pellegrino, Renato Buzio, Emilio Bellingeri, Cristina Bernini, Antonio Sergio Siri and Daniele Marré J. Micromech. Microeng. 23 035031 (2013) [3] Strain response of La0.7Sr0.3CoO3 epitaxial thin films probed by SrTiO3 crystalline microcantilevers Biasotti M, Pellegrino L, Bellingeri E, Manca N, Siri A. S and Marré D. Appl. Phys. Lett. 97 223503 (2010)

|

|